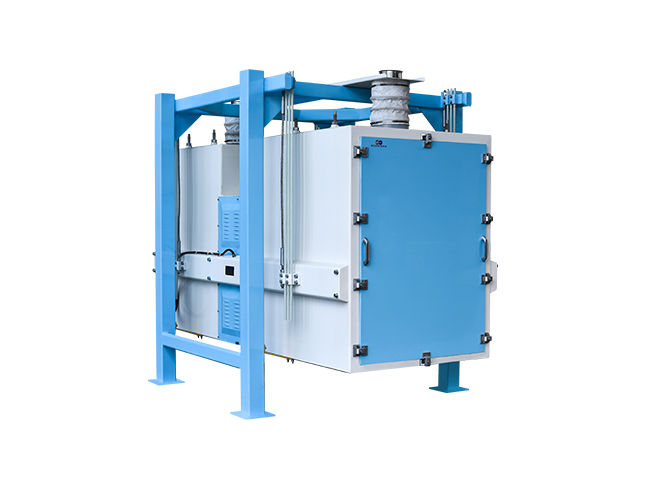

This TWIN CHECK SIFTER serves as the final security step in the milling process to ensure flour purity before storage or packing. It effectively removes bran particles and oversized material that may have bypassed earlier sifting stages. Positioned at the end of the production line, it safeguards product quality and consistency, making it essential for maintaining high standards in flour output.

| Model | Sieve Layers | Sieve Area (m²) | Capacity (≤t/h) | Rotary Diameter (mm) | Power (kW) | Dimensions (L×W×H) (mm) |

| SFS-740 | 8–12 | 6.8–10.2 | 2–3.5 | Φ40–50 | 1.5 | 2300×1450×1760 |

| SFS-830 | 8–12 | 8.3–12.5 | 5–11 | Φ45–55 | 2.2 | 2462×1751×2250 |

| SFS-1000 | 10–12 | 15.6–18.8 | 8–20 | Φ45–55 | 2.2 | 2932×1921×2250 |

| SFS-1200 | 10–12 | 23.5–28.3 | 20–30 | Φ45–55 | 4 | 3392×2121×2250 |